SECURING OT &

IOT IN INDUSTRIAL MANUFACTURING

Overview

Secure your industrial networks’ future while enhancing operational resilience.

As more and more networked devices generate wider attack surfaces, cyber dangers to industrial manufacturing are increasing.

Nozomi Networks, the leading provider of OT, IoT, and IT visibility and security solutions for industrial producers, can assist in protecting your fragile production environment.

Our comprehensive protocol support and deep OT experience give more asset coverage than any other cybersecurity solution provider. And, regardless of the facility’s age or the complexity of the challenge, our extremely precise detection of cyber threats, risks, and abnormalities enhances operational resilience.

Why is Securing Industrial Manufacturing So Challenging?

Legacy Manufacturing Equipment Was Created for Reliability, Not Security

Traditional ICS equipment, such as those used in critical industries, typically have lifecycles of decades. They are purpose-made, stand-alone systems that are developed for dependability rather than security. They frequently run sandboxed versions of OS systems and interact over proprietary or industrial protocols that lack security protections. Furthermore, they are frequently vulnerable to changes in network traffic or firmware, rendering many IT security products dangerous to use.

Manufacturing ICS has been slow to adopt network segmentation and zero trust.

Over 70% of manufacturers are on a Smart Factory path to boost competitiveness and efficiency. The integration of ICS with corporate networks and internet-based applications that results greatly expands the attack surface at manufacturing sites.

ICS network administrators, on the other hand, are hesitant to implement typical IT security strategies like as network segmentation or zero trust solutions. They are concerned about increasing the complexity and costs associated with cyber-physical process management, as well as introducing hazards to production uptime and safety.

IoT Devices Proliferate and Pose Security Risks Too

Millions of Internet of Things (IoT) devices are being added to industrial manufacturing networks in order to cut costs and provide greater value to customers. They are also being introduced to networks that are required to keep facilities running, such as access control, fire, lighting, and HVAC systems.

Many IoT devices, like legacy ICS equipment, use lightweight, stripped-down operating systems that lack standard security capabilities. Their firmware is rarely updated, despite the fact that they are constantly connected to other systems, making them an ideal target for hackers an easy target for hackers.

The inherent characteristics of manufacturing systems and facilities make them difficult to secure. It takes substantive ICS and manufacturing industry expertise to do this properly – capabilities built-in to the Nozomi Networks solution.

Securing Manufacturing Global Leaders

Everything begins with visibility. What you can’t see can’t be protected.

Good security begins with high visibility. Nozomi Networks is the market leader in OT/IoT/IT visibility and protocol support.

As you digitize your organization, you will encounter a large number of operational assets in industrial networks that must be identified, monitored, and secured. Where do you begin?

The first step is to find and identify all of your assets. The Nozomi Networks system automates asset inventory regardless of vendor, providing the most comprehensive and accurate asset coverage. By eliminating manual data gathering and giving continuous data rather than snapshots of data, we save you time and money.

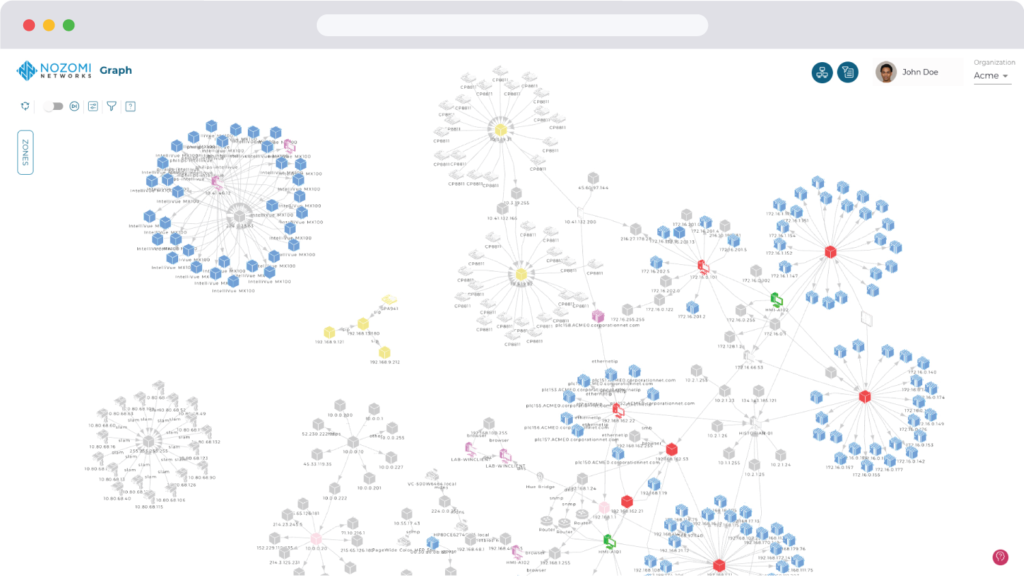

Nozomi Networks enhances your situational awareness by producing a live interactive picture of your industrial manufacturing network in addition to asset identification. It displays the full OT/IoT/IT environment and can be simply examined to display network segmentation, data flows, protocols, and other information.

A comprehensive picture of all production assets and networks minimizes cybersecurity gaps. In addition, the Nozomi Networks solution delivers visibility into your global manufacturing ecosystem and its hazards through a single pane of glass, allowing you to make informed, prioritized decisions that efficiently minimize vulnerabilities, threats, and risks.

The manufacturing and OT/IoT expertise embedded into the Nozomi Networks solution significantly improves visibility, resulting in better risk management across all of your manufacturing plants.

Try Nozomi Networks Today!

Let us put our passion for innovation

and customer success to work by

helping you ensure high cyber

resilience and reliability.